Home / 3D Metrology / Metrology Applications

Metrology Applications

When it has to be right

Discover the key trends and challenges in your industry and see how our 3D laser tracker systems and scanning solutions measure up across industries and sectors.

- Inspection and alignment of airframe assembly and structural components

- Measurement, inspection, and calibration of tooling, jig, and fixture

- Scanning and inspection of critical parts (aero engine turbine, landing gear, etc.)

- Symmetry and deformation check

- Maintenance, repair and overhaul (MRO)

- Robotic positioning technologies

- Robotics positioning and controlling in production

- Near-line and in-line inspection and quality check in production

- Measurement, inspection, and calibration of tooling, jig, and fixture

- Inspection and alignment of powertrain and vehicle components

- Automatic car body scanning and inspection

- Excellent mobility for motor sports application

- Measurement and scanning in CAD modelling and reverse engineering of parts

- Quick and accurate probing measurement of fine structures, with parts still clamped on the machine centre

- Deep probing on contours deep inside workpieces

- 3D inspection of cast and stamped parts

- Measurement of milling and eroding accuracy

- 3D scanning and tactile measurements on parts

- Alignment of machinery for improved dimensional control

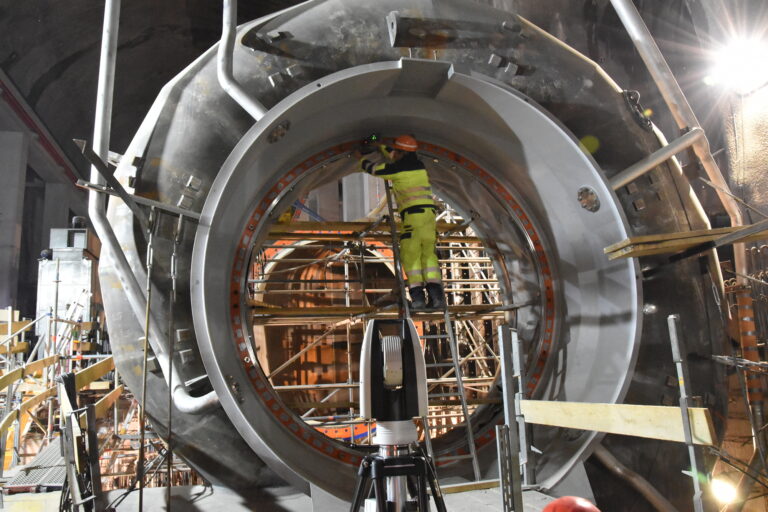

- Measurement and scanning of turbine and rotor blades

- Measurement, inspection, and alignment of power unit assembly

- Measurement, inspection, and calibration of tooling, jig, and fixture

- Solar panel alignment and panel dimensional check

- Alignment and scanning of pipes and connectors

- Large scale measurement and production monitoring

- Operation in challenging environments (outdoor, vibration, heat/cold)

- Measurement, inspection, and calibration of tooling, jig, and fixture

- Portable solution for large scale metrology in civil engineering projects (tunnel segments measurement and alignment, transport rail work, etc.)

- Large scale measurement with move station capabilities (Unified Spatial Metrology Network, USMN)

- Bogie, and wheel truck measurement in rail industry

- Hull measurement and alignment in ship building industry

- Heavy machinery measurement, inspection, alignment, and monitoring (conveyor, steel cutting, fluid compression, etc.)

- Laser tracker based measurement and fitting of large cast and machinery components

- Repeatability measurement and quality control

- Digitalising using metrology software in 3D scanning, 3D modelling, reverse engineering and quality check

- Streamlined, high speed, and high accuracy measurement

- Modern scanning technology for various scanning tasks

- Portability and flexibility for maximum time savings

- Capability to handle different materials – metal, composite, plastic, etc.

- Quick and reliable calibration of machinery

- Measurement, inspection, and calibration of specialised equipment

- Inspection and alignment of medical research nuclear reactor components

- Reference in positioning to target proton beams in radiotherapy equipment

Application Videos

Leica Absolute Tracker AT960 at Airbus Helicopter

Probing, scanning – inspection against CAD

Leica Absolute Tracker ATS600 at Temelin Nuclear Plant

Deflection analysis

Leica Absolute Tracker AT403 at Stadler Rail

Leica Absolute Scanner XL at Stadler Rail